Ensuring Safety Through Equipment Integrity in Patient Care Environments

By Billy Weingarten

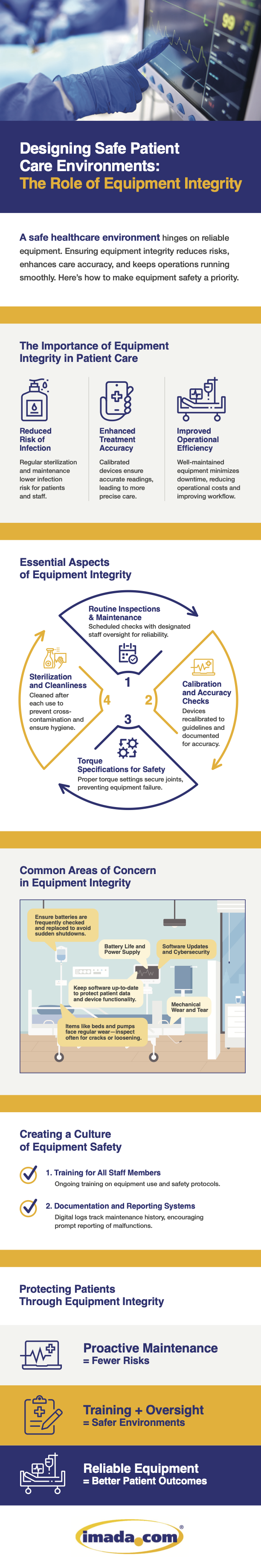

Patient safety remains a top priority in healthcare settings, and the integrity of medical equipment plays a critical role in achieving this goal. Equipment that functions reliably under all conditions is essential for creating safe environments where patients receive care without risk of harm from device failure or malfunction.

The importance of equipment integrity

Equipment integrity refers to the condition and reliability of medical tools and systems used daily in healthcare facilities. Faulty or poorly maintained equipment can lead to inaccurate diagnoses, treatment errors, or even accidents during patient care. Regular inspection, maintenance, and calibration ensure that devices operate within specified safety parameters. This is particularly true for critical medical devices such as infusion pumps, ventilators, and diagnostic machines, where even minor malfunctions can have significant consequences.

One way to uphold equipment integrity involves the use of torque testers. These devices verify that fasteners and connections in medical equipment meet precise torque specifications, which is crucial for preventing loosening or failure during use. Maintaining proper torque levels contributes to the overall durability and safety of healthcare tools, reducing the risk of mechanical failure that could compromise patient care.

Integrating equipment integrity into healthcare design

When designing patient care environments, it is essential to consider not only the placement and accessibility of medical equipment but also protocols for their ongoing maintenance. Facilities should establish clear schedules for inspection and calibration of devices, supported by staff training on proper equipment handling. This reduces wear and tear caused by misuse and helps identify potential issues before they affect performance.

Moreover, healthcare facilities benefit from incorporating advanced monitoring technologies that track the condition of equipment in real-time. Such systems alert maintenance teams to irregularities, enabling quick response and minimizing downtime. This proactive approach aligns with patient safety objectives by ensuring devices are always ready for use without unexpected failures.

Maintaining equipment integrity also supports regulatory compliance and accreditation standards, which often emphasize the safety and reliability of medical devices within care settings. Healthcare providers can enhance trust among patients and staff by demonstrating a commitment to high standards of equipment management.

Equipment integrity directly impacts patient outcomes and operational efficiency. When medical tools perform as intended, healthcare professionals can focus on delivering quality care without distractions caused by equipment issues. Investing in proper maintenance tools and implementing comprehensive management systems are vital steps in sustaining a safe patient care environment.

Patient safety depends on many factors, but ensuring equipment integrity stands out as a fundamental pillar. Healthcare facilities that prioritize the reliable operation of their medical devices contribute to safer, more effective care experiences and foster confidence among patients and providers alike. For more information, look over the accompanying resource below.

Billy Weingarten is Digital Content Specialist for Imada. Weingarten has over a decade of experience in supporting precision force and torque measurement instruments. His extensive knowledge includes software and test system configuration, instructional video production, calibration and data analysis.